Jan 30th, 2013

Today is the second day of FlexTech’s 2013 Flexible and Printed Electronics Conference. It’s very popular with about five hundred attendees and sixty exhibition booths (flexconference.org).

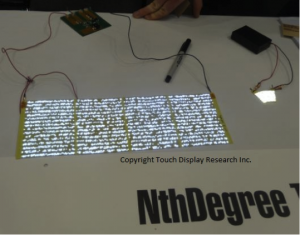

At Nth Degree Technology’s booth they demonstrated several types of printed LED lighting. One is a transparent blue LED light, two are flexible white LEDs (see image below), another is used as a signage.

Source: Nth Degree Technology, photo by Jennifer Colegrove

The construction process for the printed LED lighting:

- First, tiny blue LEDs were built using traditional wafer fabrication technologies.

- Then the tiny LEDs were mixed into a special ink.

- The ink was applied using a high-speed printing method onto conductive substrates (plastic or glass).

- If there is a need to change colors, a phosphor layer is added on top of the blue LED lighting.

What kind of application will this flexible LED lighting be used for? What is the time-frame for this this lighting to come to market? What’s the comparison of printed LED lighting vs. OLED lighting vs. EL lighting? A detailed analysis will be in the upcoming Touch and Emerging Display Monthly Report, Feb 2013 issue.

Thanks for reading,

Jennifer and team