July 15, 2015

I recently had a chance to interview Kodak’s VP of Functional Printing group, Mr. Brian Marks. Mr. Marks indicated Kodak is currently working on two metal mesh technologies: 1. Silver metal mesh, and 2. Copper metal mesh.

As we covered before in Touch and Emerging Display monthly report, UniPixel bought the Atmel’s XSense business and facility in Colorado in April 2015.

On April 27, 2015, Kodak announced it is committed to moving forward independently with development of copper mesh touch sensor technology, following UniPixel’s decision to withdraw from joint activities with Kodak.

“We are pleased to have full control over the technology development program and excited about the business opportunities ahead. We expect to have products based on this technology in the market before the end of this year,” said Philip Cullimore, President – Enterprise Inkjet Systems Division and Micro 3D Printing & Packaging Division.

UniPixel and Kodak signed partnership agreement back in 2013. But after about 2 years, the partnership broke up.

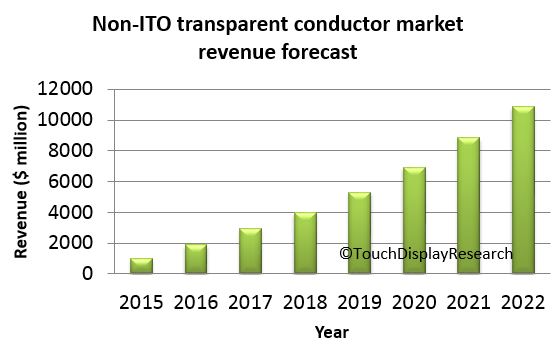

In the recently published “ITO-replacement: non-ITO transparent conductor technologies and market forecast 2015 report“, Touch Display Research forecast the non-ITO transparent conductor market will have rapid growth and reach $10.9 billion in 2022.

Figure: ITO-replacement market forecast.

Source: Touch Display Research Inc. ITO-replacement 2015 report.

More analyst about Kodak touch sensor technologies, supply chain and business will be in the “Touch and Emerging Display monthly report”, July 2015 issue.

Thanks for reading,

Jennifer and team